G.P. Vehicle Engineering offers design and prototype construction services starting from the initial idea of the client and can follow them up to the mass production, always by our customers' side.

PRELIMINARY PHASE

Pre Study

Project Book

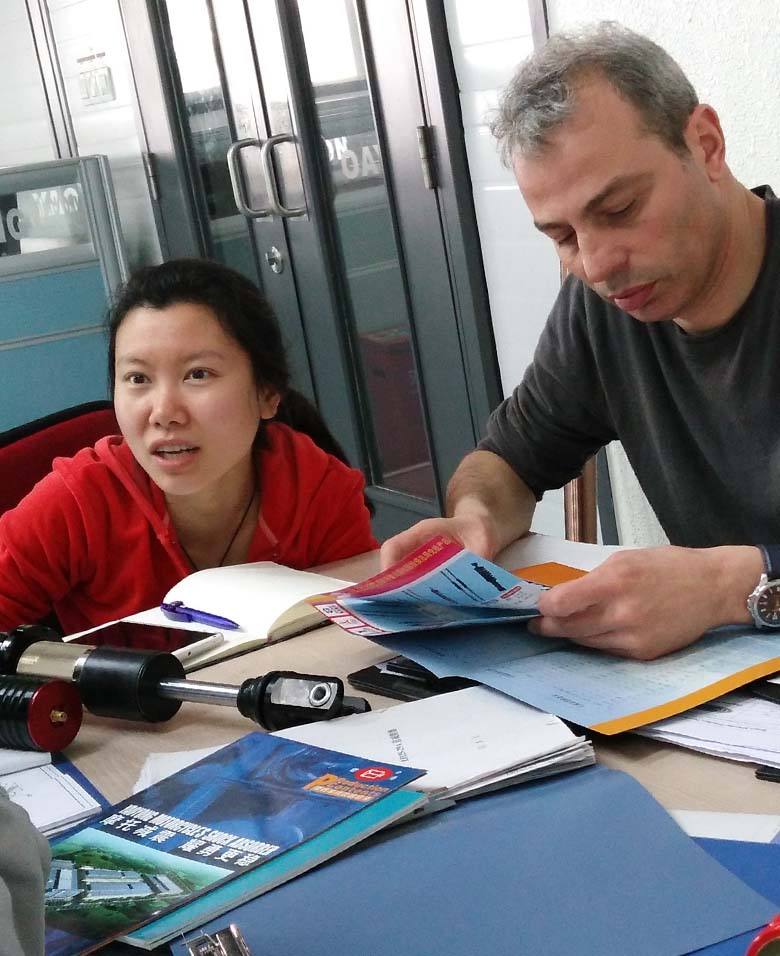

Each new project is born from the need to offer "something more" than what already exists on the market. For this reason the first step is always a careful analysis of the contemporary "state of the art" and a meticulous technical analysis of the competitors' vehicles.

The purpose of this work is to offer a series of information, dimensions, estimated performance, legislative framework to the customer on what he can expect to receive from the project before "pulling a single line" on a CAD.

The document that encloses all this initial information is the "Project Book".

DEVELOPMENT

Mechanical-Technical

Design

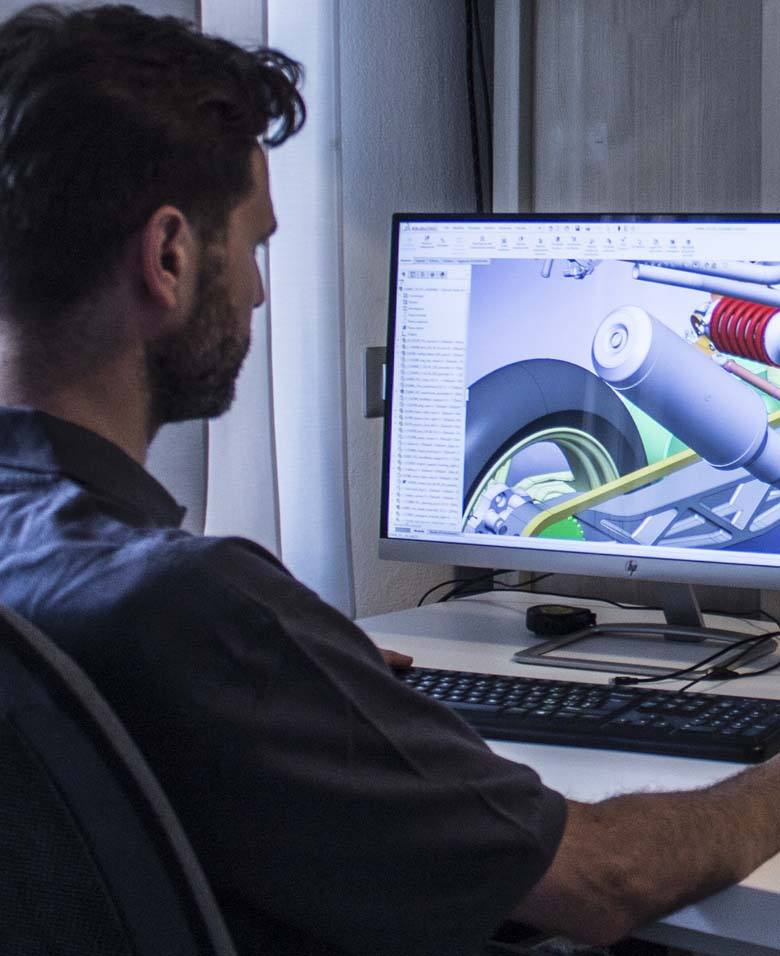

Starting from the information in the Project Book, the whole project is carried out in 3D CAD design, with attention to safety, performance, ergonomics, comfort, ease of mass production, cost effectiveness, according to the priorities and needs of the customer. We use different design software according to the type of work, 3D modeling, suspension calculation, FEM analysis.

The final document that contains all this work is the "Vehicle Layout".

REALIZATION

Prototypes

Construction

The construction of the prototypes is a fundamental part of the work that takes place in G.P. The construction and assembly of the frames is carried out totally in-house, while the machining on machine tools, the tooling of the jigs and the surface finishes are carried out externally. All incoming materials are checked from our dimensional lab.

At the end of the prototype assembly a final dimensional measure of the vehicle is carried out internally.

G.P. also deals with the realization of bodywork parts or plastic/ABS/VTR components always using external suppliers We have an internal modelling department that deals with the assembly of the bodywork or the construction/adjustment of the plastic components.

VERIFICATION

Road test

and trials

Once assembly and dimensional checks are completed, the vehicle is tested. G.P. has the possibility to perform chassis fatigue tests on cam drum roller bench internally, and to organize and perform road tests using certified external testers.

The type of tests and the mileage accumulation follows the customer's needs, G.P.'s structure using external laboratories is able to provide assistance and certified reports for any customer need, including ministerial approvals.

CUSTOMER SUPPORT

Assistance to

industrial development

In many cases G.P.'s work does not end with the delivery of the project and the prototypes, but we are able, thanks to the considerable experience of some members of our engineering team, to assist and support our customer in the choice of suppliers and in the deliberation operations of the components during the whole industrial development up to the series production. We often assist our customers in the search for suppliers both in Europe and Asia.